Damen Shipyards, DNV and NAPA have together made a major advance in ship design processes by using the new Open Class 3D Exchange (OCX) standard to involve classification societies at an earlier stage in the design phase of a project than before. This increases designer and owner confidence in the concept design and accelerates the entire design approval process without any loss of detail or rigour.

OCX is a new standard for 3D model-based class approval, developed to break down the barriers between different design and classification software platforms so as to enable the smooth exchange of idealized geometry and metadata. The OCX 3D model can also replace the traditional 2D structure drawings for classification purposes, thereby saving time for the yards and allowing class associations to respond more quickly to designers’ needs.

It is the result of the joint industry project ‘Approved (2016-2020)’ headed by DNV and which is now owned and managed by the OCX Consortium established in 2021. Consisting of more than thirty industry leaders, it is committed to promoting and maintaining the standard, including all the major classification societies as well as leading CAD providers, designers and yards.

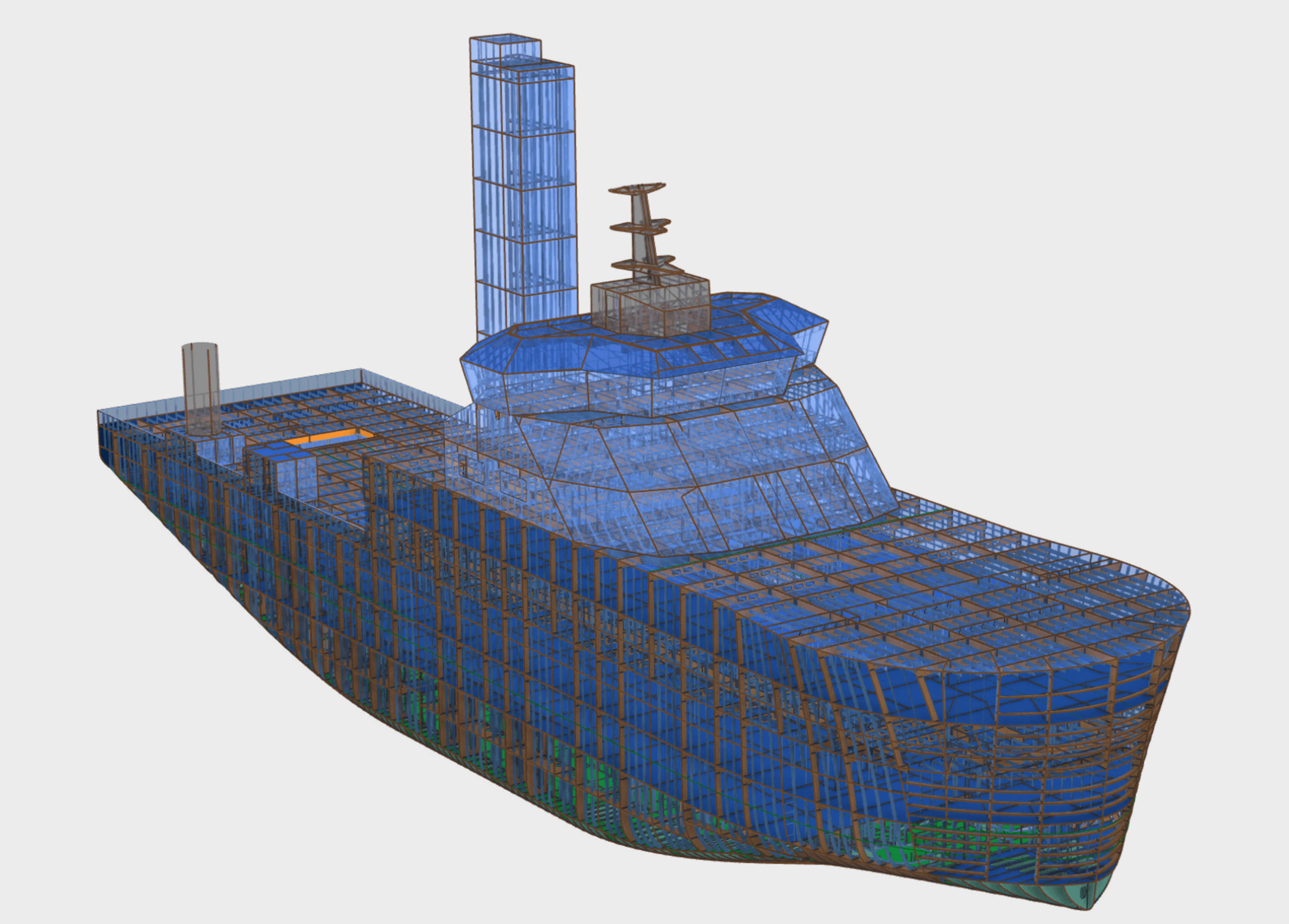

With increasing pressure to deliver vessel designs quickly, the early engagement of classification societies can increase designer and owner confidence in the concept design. With this in mind, Damen Engineering involved DNV classification experts in the first review of its new design for a Commissioning Service Operation “Walk to Work” Vessel.

This involved using cutting-edge technology based on 3D model exchange and approval through the OCX file format. Damen engineers were already using NAPA’s 3D design tools, which enable the export of 3D models in the OCX format. This functionality allowed Damen and DNV to work in parallel on the same 3D model, avoiding the time and effort previously needed to agree and prepare 2D documentation.

“Environmental, safety, regulatory and other external pressures, combined with the competitive need to create ever-better designs, meant that doing things the way we always did them was no longer sufficient,” says Katarzyna Romantowska-Jaskólska, Manging Director at Damen Engineering. “The OCX format allowed us to take a new approach that is beneficial to everyone involved in the development of the vessel design and the project execution process. In collaboration with DNV and NAPA, we arrived at a solution that connects disciplines and facilitates quick decision-making while reducing risks in the early stages of the design.

“The earlier class starts the design approval process, the easier it is to find good rule-compliant design solutions in cooperation with the yards,” adds Ivar Håberg, Director of Approval at DNV. “By using the OCX file format to exchange information on 3D design models, we can interact and cooperate more efficiently with the designers and yards in the early design development phase.”

“What OCX does is that it brings together the engineers, shipyard and classification society in a single environment in real time,” continues Katarzyna Romantowska-Jaskólska. “The process starts with the engineer or designer creating a basic model that can then be filled out or certain spaces set aside to be worked on later. At the same time the classification society can monitor progress in real time to ensure compliance with rules and regulations as well as strength and other parameters. The format also allows for the model to be exported to another parties, such as the owner, for viewing in a 3D environment.

“By accelerating communications, questions can be raised straight away over the phone as all those involved are looking at the same images. The information entered is then integrated across all the areas of knowledge so the impact of a change made in one area can be seen clearly right across the design. By combining the two environments – classification and design –in a single interface we find that the average time needed for the basic design is reduced by up to 30%.”

There is still some way to go before OCX enters the mainstream of ship design. The Japanese shipbuilding sector is the most advanced in the adoption of the OCX standard. Damen is leading the pack in Europe and there the next move is to roll it out across the various product groups. The format itself is also developing with DNV very much engaged in demonstrating the benefits that come from accelerating the classification process. Progress will be made on a project by project basis, with shipyards hopefully experiencing the benefits to be had from the concurrent design process.

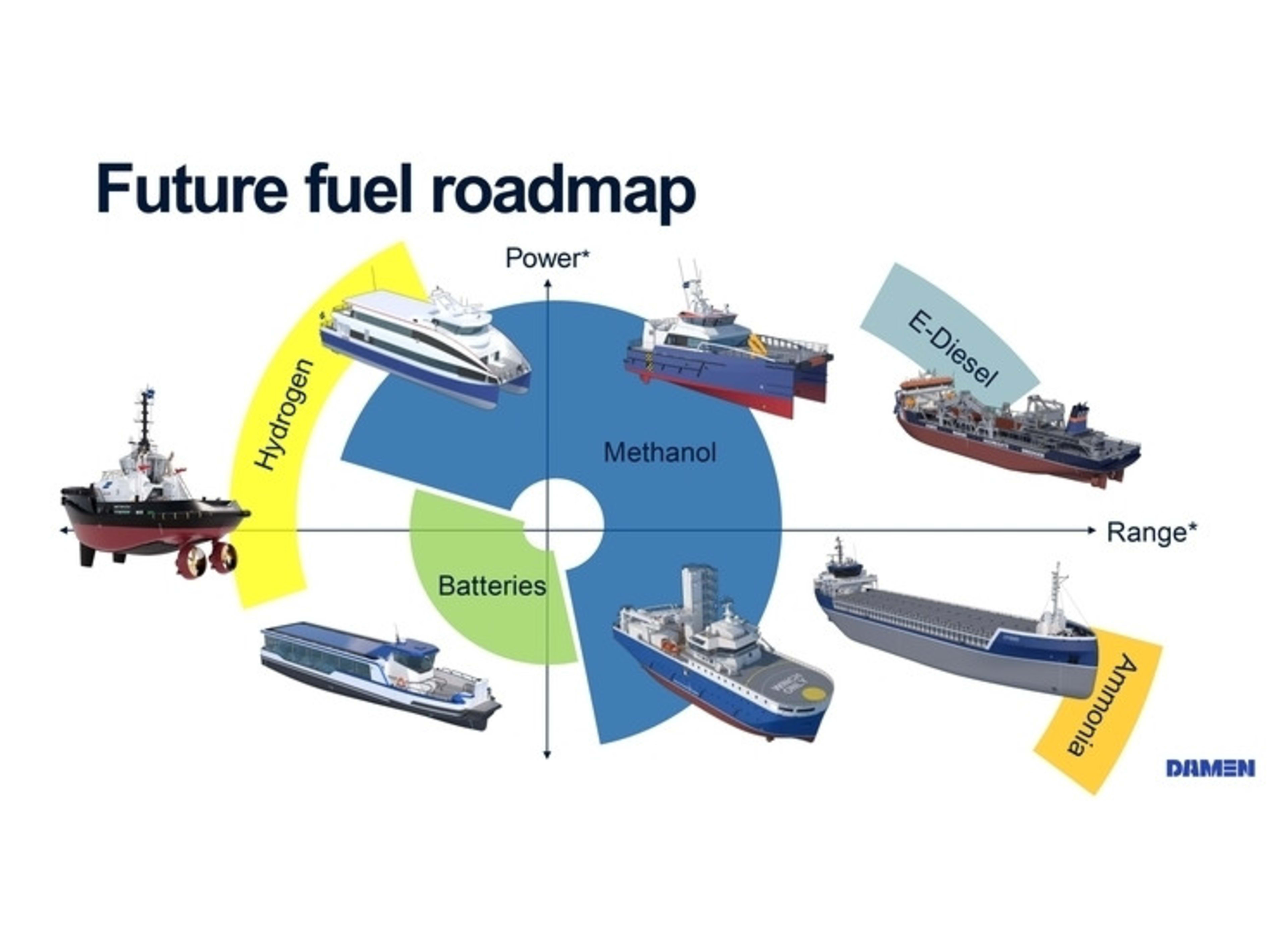

The move towards decarbonising the shipping industry is expected to contribute to this. The OCX standard will enable owners to be confident that their new vessels are compliant with the necessary regulation from the outset, with the classification societies able to monitor and advise right from the start and the implications of any changes immediately apparent right across the vessel.

“The benefits of this new way of designing for compliance may not be immediately apparent to most owners,” concludes Katarzyna Romantowska-Jaskólska, “but they may well feel that everything works more smoothly and efficiently from the outset. It’s going to take a few years for the maritime sector to fully adopt it, but the result will be better quality and faster deliveries.”

Receive our newsletter

Get Damen updates, news and amazing offers delivered directly to your inbox.