Ship repair and maintenance

In-house ship repair and maintenance solutions for any problem

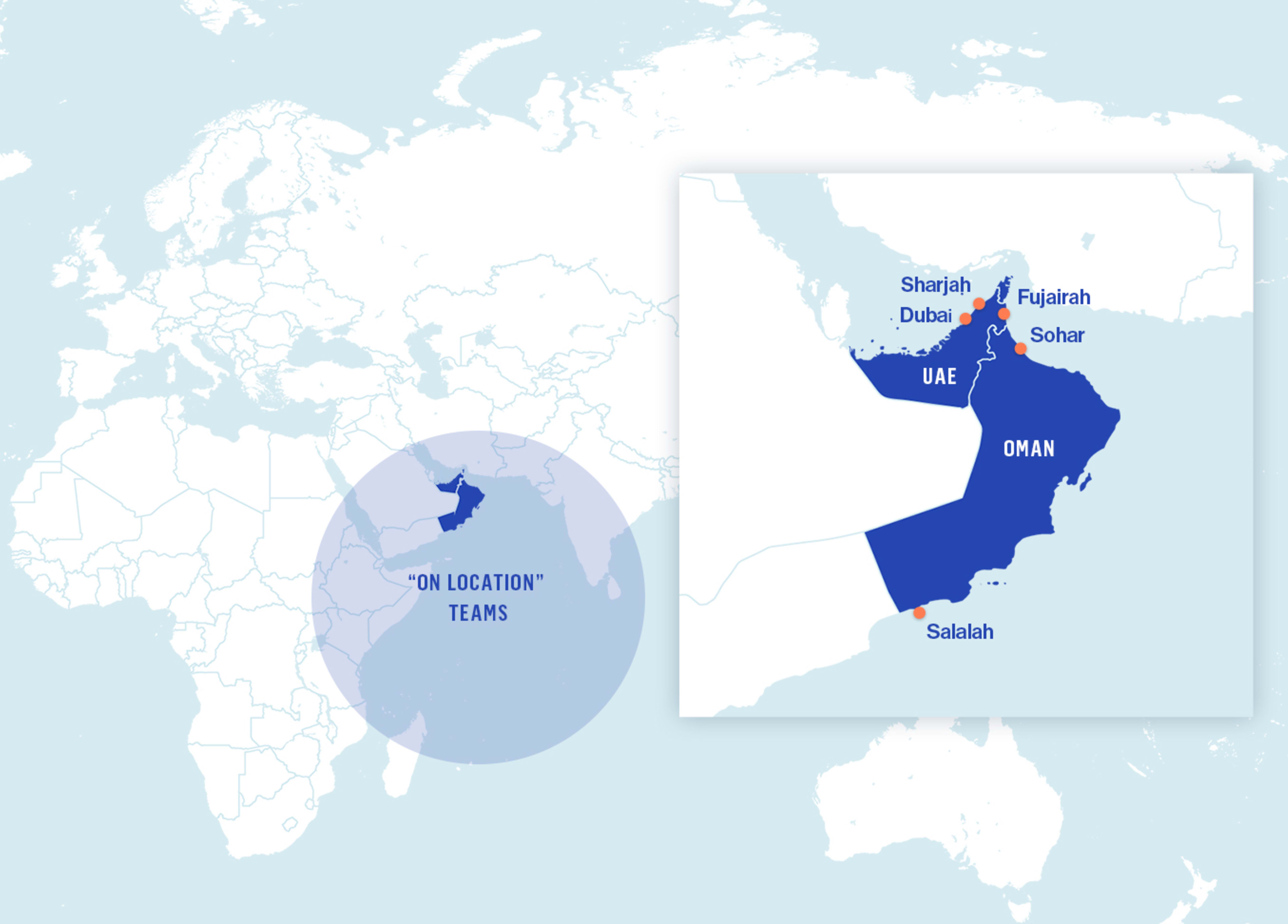

Major ports and anchorages in the UAE

Albwardy Damen offers ship repair and maintenance services from our locations in Sharjah, Dubai and Fujairah. With all major trades in-house, we are able to offer vessel repairs throughout the Middle East, from our shipyards and offshore. With cutting edge workshop facilities and extensive dock capacities, our company operates to the highest safety and environmental standards. Our scope covers a wide range of marine services for both commercial and navy operators.

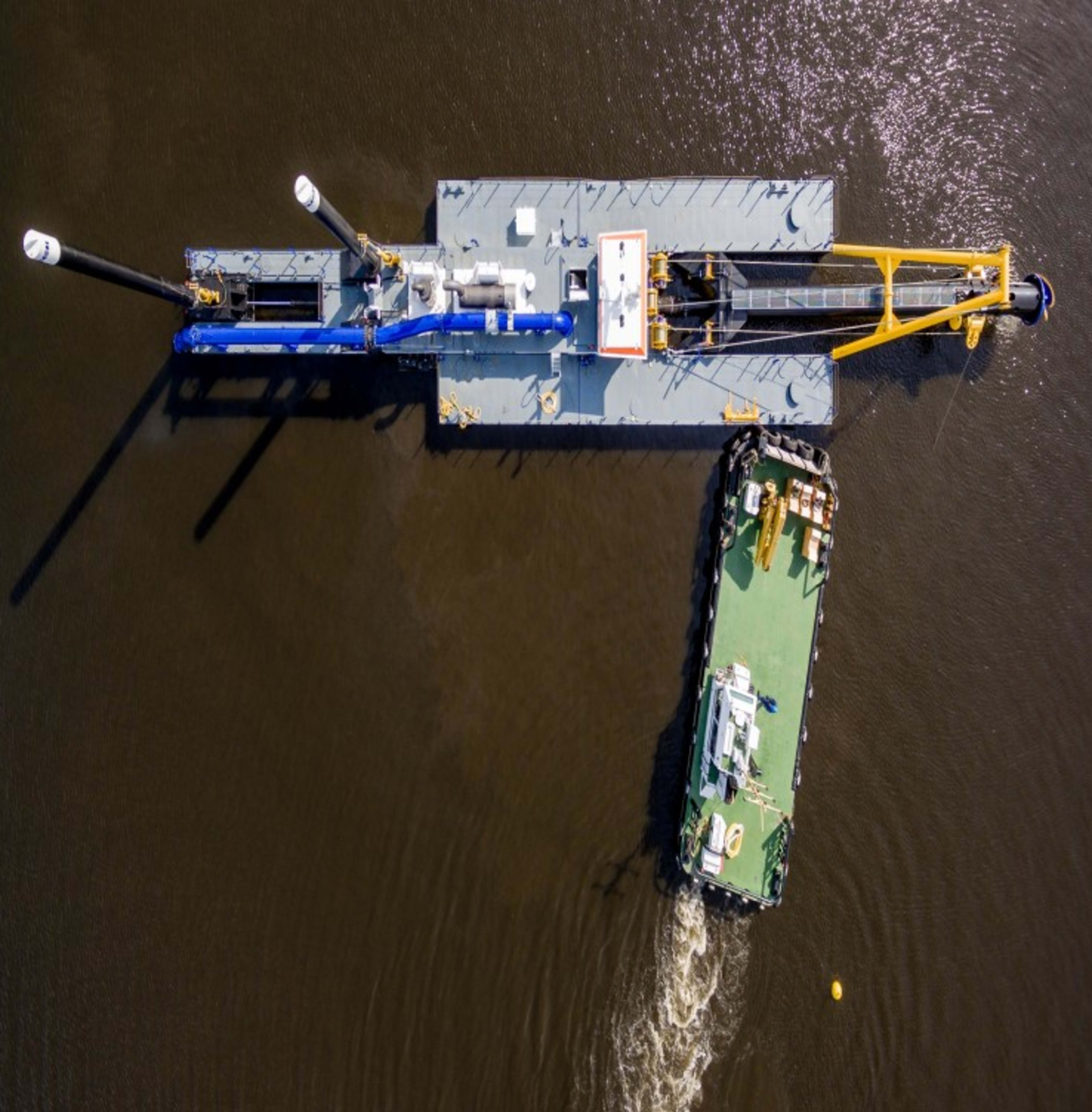

Vessel repair in dock and offshore

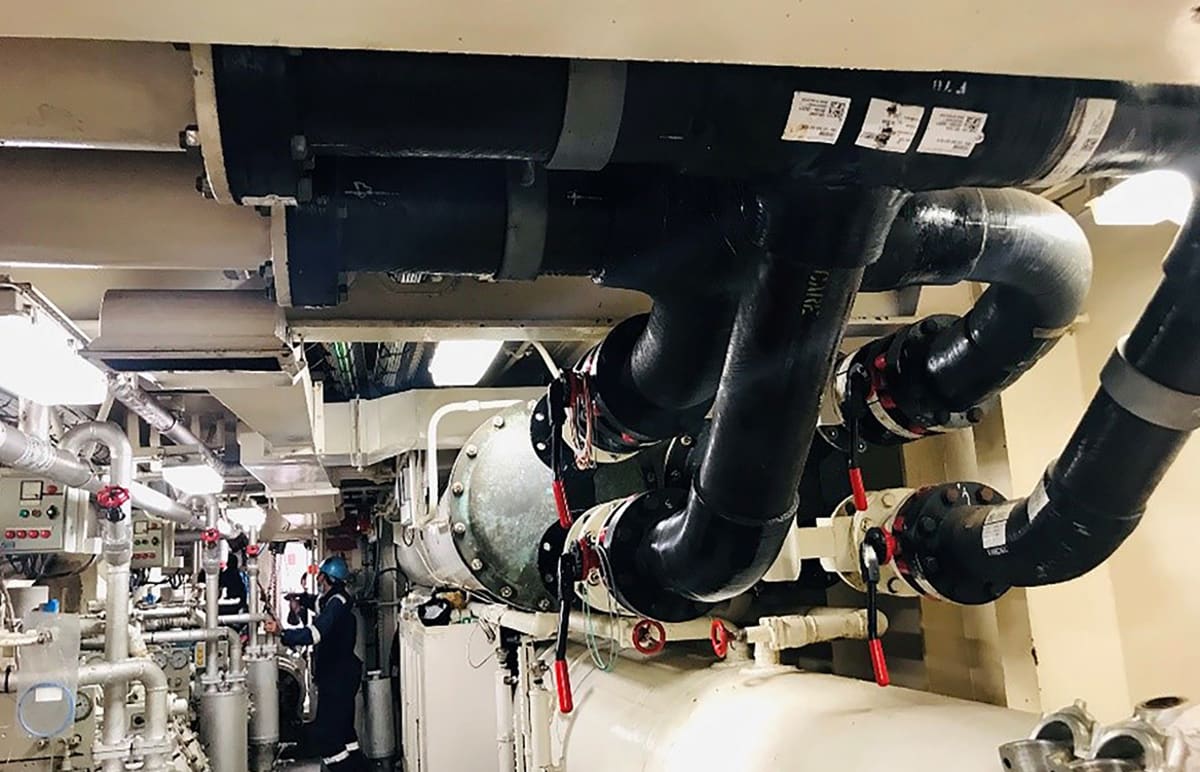

Our company carries out a wide range of vessel maintenance services. With an in-house team of experts and state-of-the-art facilities we deliver steel, aluminium, mechanical, carpentry, blasting, painting, hydraulic and electric repairs to vessels of all types.

Ship repair services

Our locations

Markets we serve

“Last year has been extremely tough for us all, however Albwardy Damen’s level of service has remained unchanged, communication with the project management team is excellent and all work is completed in a very safe and professional manor.”

“This mission was not an easy one, it was a great challenge. However, we had a big confidence in our partner in business, Damen who met and exceeded our expectations in making it happen despite all challenges.”

“If any other vessel owners ask for any services, my first preference would be to recommend Albwardy Damen.”

Albwardy Damen highlights

Safety is our highest priority

We are committed to continuously maintaining a safe and healthy workplace in all our operations. We recognise that we work in a dynamic industry involving potentially hazardous equipment and operations.

Read more1500 people ready 24/7

We have a dedicated team of 1500 people in three UAE locations, who are ready to support our customers 24/7.

One-stop-shop

We have a large team of in-house specialists who can pick up the requests of any level of complexity. We are engineering, building and repairing steel or aluminum vessels. Our mechanical and electrical departments are all in-house. We have a large experience in retrofitting and conversions.

All major trades in-house

We have all major trades in-house, mainly carried out by our own staff. We offer 3D scanning, retrofitting, propeller repairs, thruster repairs, GRE piping, hydraulic and electric repairs. We have a multi-disciplinary Engineering and Production support team in-house.

Quality & Safety at the right price

We are committed to continuously maintaining a safe and healthy workplace in all our operations. With all key competences in-house we deliver to the highest technical, environmental standards at the right price.